Industry 4.0 is widely recognised to have originated in 2011, and now, after over ten years, the manufacturing sector is well and truly in the midst of a data-driven revolution. According to a World Economic Forum whitepaper, Industry 4.0 will spur enterprises to join forces in interconnected value networks to leverage data and analytics applications to fuel productivity, cultivate new customer experiences, and make a significant impact on society and the environment.

According to Gary Coleman, Global Industry and Senior Client Advisor, Deloitte Consulting has said that “the Fourth Industrial Revolution is still in its nascent state,” but as this era unfolds further, it will continue to unlock an unprecedented amount of data for the manufacturing industry to manage that will also need to be safeguarded. The global data privacy software market has been experiencing exponential growth, which has been fuelled in part by the adoption of the Internet of Things (IoT) across various sectors. As a result, the compound annual growth rate (CAGR) has matured to 40.9 per cent, underscoring the importance of data privacy and security at this pivotal time.

The rise of data-driven processes in manufacturing

If mathematician Clive Humby is right, and “data is the new oil”, then manufacturers are sitting on a goldmine of information they can use to make critical decisions. The manufacturing sector has more data than ever before, thanks to the rise of digital transformation, which has ushered in disruptive trends into the manufacturing sector, such as IoT, machine learning, data and analytics and hyper-personalisation. All innovative technologies, though transformative, also generate a large amount of data to analyse.

As the manufacturing industry becomes increasingly dependent on data, the greater the demand will be for sophisticated analytical tools and robust data security measures. In an industry survey comprising 1,300 manufacturing executives, roughly three-quarters have identified the requirement of advanced analytics for sound decision-making becoming increasingly critical for businesses, much higher than three years ago. Additionally, a skilled workforce trained in data science, AI, and advanced analytics will be required to analyse insights and manage the influx of data.

To successfully employ data-driven processes, manufacturers must overcome several obstacles. According to the Harvard Business Review, these blockers vary from capturing and scrutinising extensive amounts of data, overseeing supply chains effectively, and navigating web-based technologies and production. Nevertheless, the advantages of data-driven manufacturing, such as boosted efficiency and advanced decision-making, make it a vital approach for the industry’s future development.

How does data drive smart and sustainable manufacturing?

Industry 4.0 unlocks numerous sustainable opportunities, but it also can be detrimental to manufacturers that do not commit to global environmental, social, and governance (ESG) initiatives. Manufacturers risk a loss of reputational standing, falling behind competitors, or becoming obsolete in the industry. However, by being armed with intelligent data stemming from digital transformation, the manufacturing industry can embrace innovation and open new sustainable pathways.

Data aids intelligent and sustainable manufacturing through real-time monitoring, predictive maintenance, and process optimisation, leading to minimised waste, enhanced efficiency, and reduced environmental impact. If the manufacturing industry can harness the avalanche of data acquired through digitalisation, big data, and advanced analytics, they can begin to support process optimisation, reduce waste, and, lastly, drive sustainability in their processes. These are only some of the benefits manufacturers can unlock.

The potential benefits using data for sustainable manufacturing

According to the Global Lighthouse Network Fourth Industrial Executive Survey, over three-quarters (77 per cent) of executives surveyed said sustainability, productivity or resilience was their top priority and data can act as a driver for improvement for all of the above.

1. Improved efficiency

Using data analytics, manufacturers can identify inefficiencies in their production processes and address them to optimise resource utilisation and reduce waste. By making data analytics another key feature of intelligent factories, data will add an additional layer of intelligence to operations to quickly identify and fix gaps while improving existing processes.

2. Cost reduction

According to the United States Environmental Protection Agency (EPA), committing to sustainable manufacturing will uncover data-driven insights and can aid manufacturers to reduce resource and production costs by optimising energy use, shrinking waste, and augmenting process efficiency.

3. Enhanced product and service quality

Manufacturing roughly makes up two-thirds of the world’s total GHG emissions, but by leveraging data and advanced analytics, manufacturers can enhance the quality of their products and services, leading to less waste from defects and returns.

4. Optimised value chains

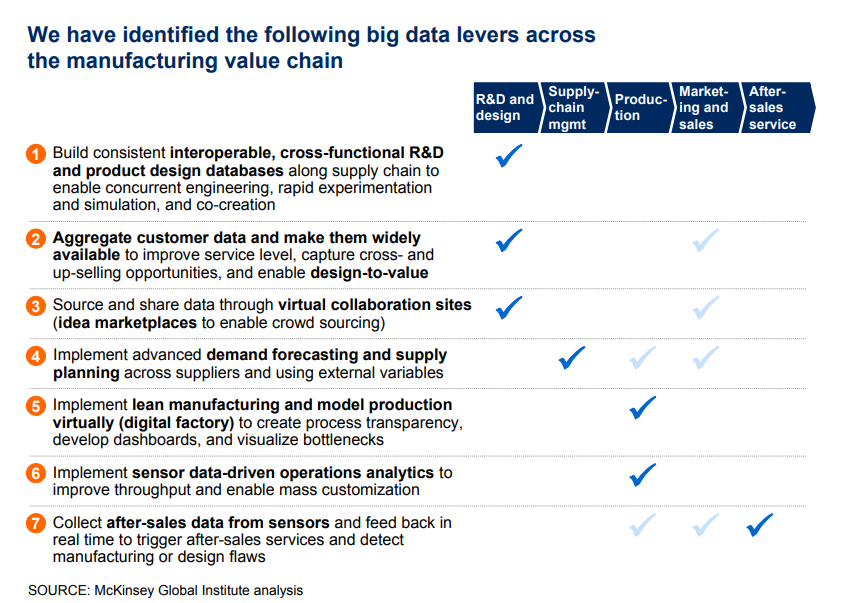

Big data offers a wealth of opportunities, including supporting manufacturers in enhancing and streamlining their value chains, augmenting return on capital, and making their operations more sustainable. McKinsey Global Institute analysis has found seven big data levers across the value chain, as illustrated in this infographic below:

Challenges of using data for sustainable manufacturing

According to the Harvard Business Review, data implementation has driven Industrie 4.0 in Germany, the Internet of Things (IoT) in the United States, and 物联网 (wù lián wăng) in China. Each are concentrated around employing big data and analytics to reshape manufacturing, and yet, significant challenges have emerged to include:

1. Data integration

One of the most significant obstacles in data application lies in integrating diverse datasets, such as structured and unstructured from various sources, into machine logs, enterprise systems, and sensors. It can be a complex undertaking to harmonise these disparate data sources in a way that allows for effective analysis and utilisation.

2. Data quality and accuracy

You are only as good as the data you are given, and to be relevant, manufacturing data must be accurate and reliable. However, data quality can often be murky due to considerations like sensor errors, missing data, or irregularities in data collection methods.

3. Data analysis skills

The Bureau of Labor Statistics (BLS) forecasts a 36 per cent growth in employment in this field by 2031, but in a State of Data Science report, 63 per cent of respondents indicated they were moderately worried about the field’s talent deficiency. Due to a lack of qualified data analysts, not every manufacturer has the luxury of properly analysing their big data into actionable insights.

4. Data security and privacy

With the increase in data collection comes a spike in risk of data breaches. Ransomware attacks, cyberattacks from nation-states and distributed denial of service (DDoS) attacks are all on the rise and manufacturers must have robust security measures in place to safeguard sensitive data.

Data governance in manufacturing

Using data intelligently within the manufacturing industry will aid the adoption of sustainable principles but can also offer valuable benefits such as lowering costs, increased productivity, and aligning with ESG principles, but only if data governance is prioritised. The cost to a manufacturer that does not heed the warning of governments will be dear, amounting to fines, loss of reputation, and ultimately, business failure.

To avoid risk, manufacturers must have a strong data governance foundation that defines clear policies, procedures, and responsibilities for managing data across their enterprises.

The future of data privacy and security in sustainable manufacturing

Manufacturing, traditionally a productivity trailblazer, is now stepping into the era of Industry 4.0, which will yield an unprecedented volume of big data and the promise of significant gains. However, with the industry’s expansion into a global activity featuring extended supply chains, the risk factor has also escalated.

Data privacy and security will play a pivotal role in the transformation of manufacturing to include ESG values and sustainability practices and initiatives. Manufacturers, in response, must invest in data protection technologies promptly and adopt a forward-thinking approach because the future of sustainable manufacturing will be designed by those who can stay one step ahead and efficiently leverage their data while ensuring its safety and privacy. To learn how to do just that, find more information about our mission here.